Precision components for hydrogen systems are subject to special surface quality requirements. Whether stainless steel or aluminium, we are the right partner here.

Green hydrogen, produced using electricity from renewable resources, is seen as crucial to the energy revolution. Buses, trucks, ships and even planes powered by hydrogen will all help achieve climate goals in the transport sector. But this requires the corresponding infrastructure. This is where we come in, producing precision parts precisely to customer specifications.

Ensuring smooth surfaces

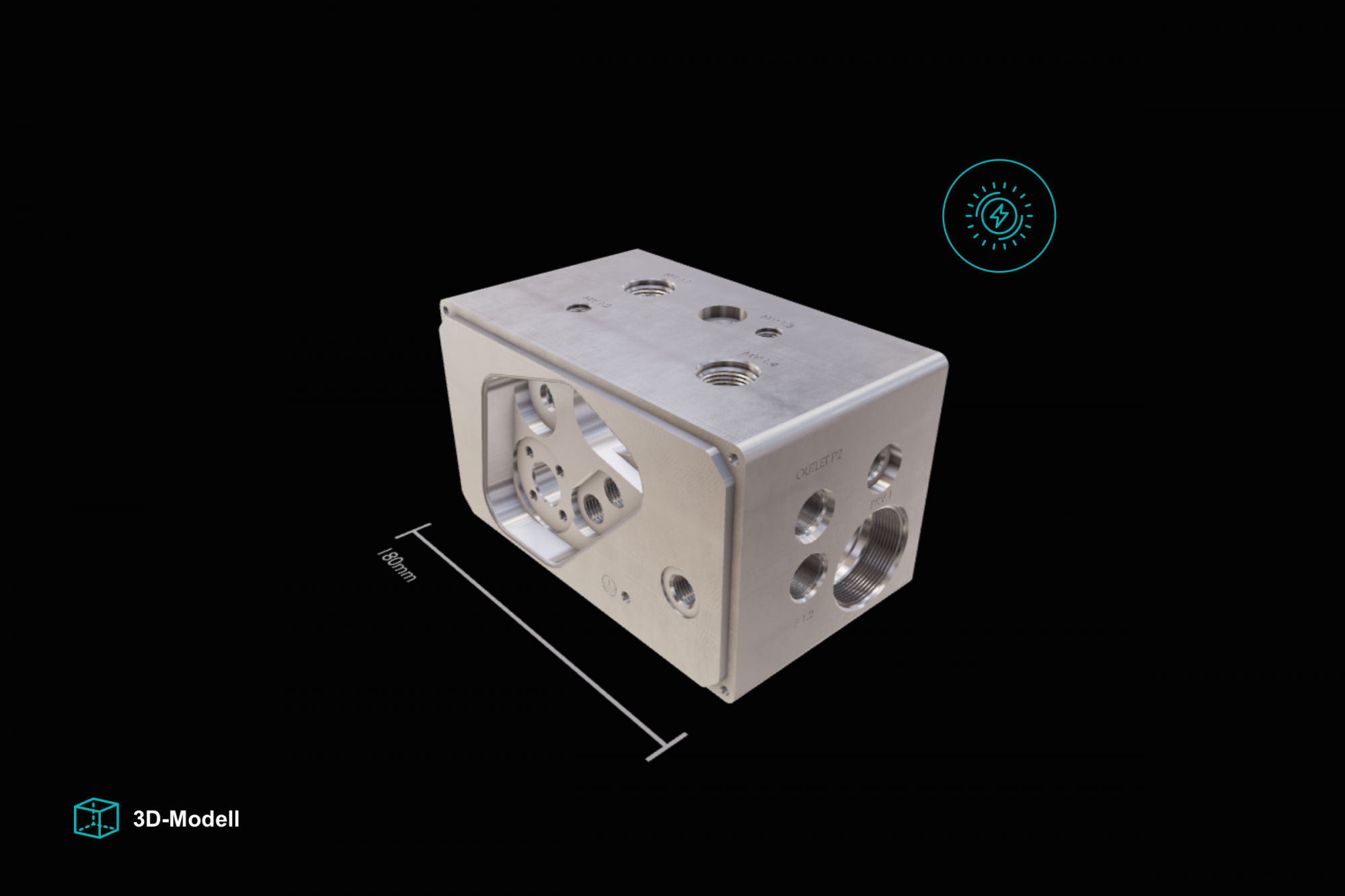

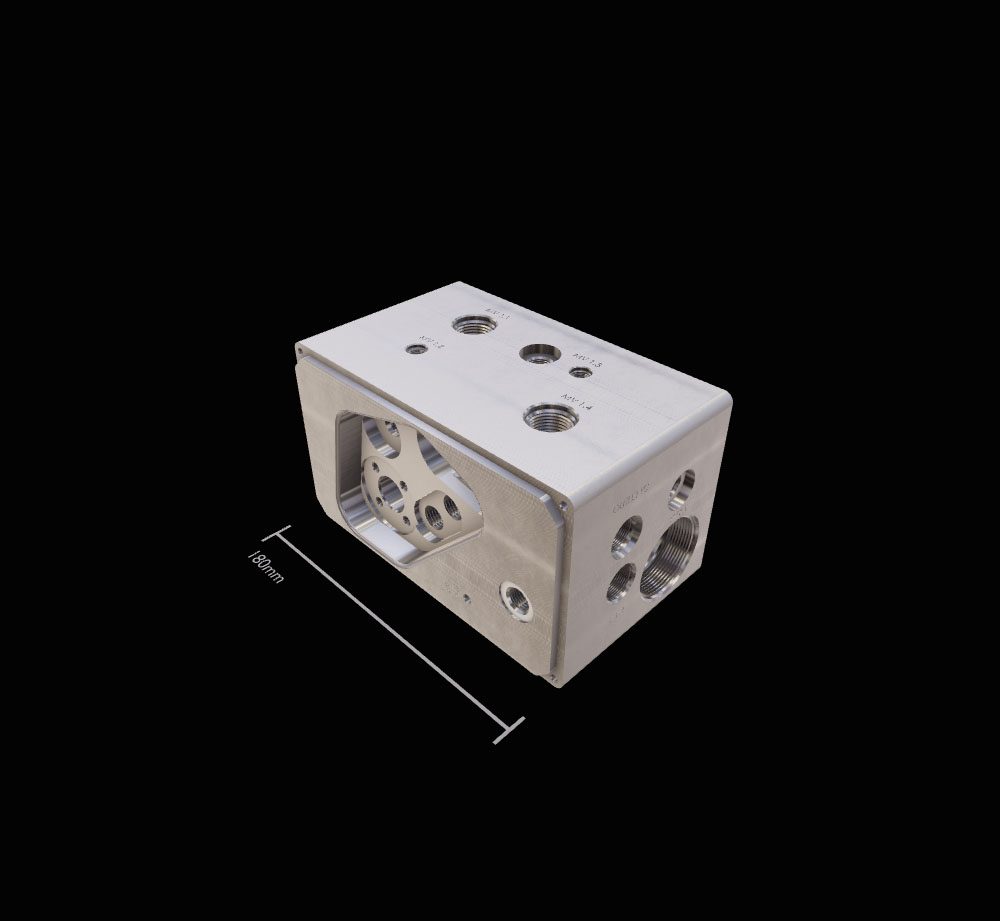

A good example are the connection blocks for hydrogen systems or housings for gas handling units (GHU), which feature lots of boreholes, grooves and surfaces. “The stainless-steel precision parts are used in tank systems, for example, that are subjected to up to 700 bar of pressure”, explains Sascha Recker, who is responsible for sales and project management. As a result, all of the surfaces and grooves in the seals must be processed with extreme precision so as not to exceed a surface roughness of Rz 1.6 mm. Recker continues: “We have already made a series of prototypes for one customer. They worked so well that we are now producing the first series parts.”

From stainless steel to aluminium

As well as GHU housings made from stainless steel, hydrogen systems also use components made from aluminium. These are fitted in special valves, for example. Here, the surface quality requirements can be even more demanding. “We achieve even smoother surfaces on the aluminium components because we can use PCD milling cutters here”, explains Recker. “This allows us to fully meet customer requirements here as well.”

Always one step ahead

Working together with customers like you, we see great potential in the area of hydrogen technologies. We are proud to be among the first companies to be active in this market, and are using this advantage to establish efficient production processes and develop solutions for the challenges to come. One important area that we have identified, for example, is ensuring that boreholes in connection blocks are free of burrs. The solution here is water jet deburring, which we offer in collaboration with an expert partner. Compared to other processes, water jet deburring ensures no deterioration in quality. You can therefore rest assured that as your one-stop shop for precision parts, we have the right solutions for your specific challenges in hydrogen engineering. Feel free to get in touch.