Co-Engineering

Whether you are a systems provider or a start-up, you can benefit from our expertise in machining.

We offer support from concept development and prototyping all the way to series production.

Based on your plans, we can optimise your parts so you can produce them more economically without compromising on quality.

Supply-Chain-Management

As a one-stop shop, we deliver precision parts and assemblies in outstanding quality.

We offer an all-round package based on your plans and specifications.

This can cover everything from material purchasing and tool selection to mechanical production and heat or surface treatment by our partners.

We can also provide assembly and functional testing, quality assurance, packaging and shipping.

Production

We use a fleet of cutting-edge machinery (2-5 axis CNC turning, 3, 4 and 5-axis CNC milling).

We specialise above all in turning (diameter 10-300 mm, length max. 500 mm) and milling (dimensions up to 500 x 500 x 500 mm).

From prototypes and small series of up to 200 parts all the way to large series with up to 10,000 parts, we produce your precision components quickly and reliably.

End processing

The end processing zone is where we give your components the final touches.

This ranges from honing and non-cutting thread rolling to barrel finishing and flat grinding.

We also collaborate with our reliable partners for heat and surface treatment.

After all this, customers get precision parts ready for use.

Surface treatment

Do your precision parts need additional surface treatment? We work with approved suppliers to give you just this.

Whether you need painting, phosphating, passivating, cadmium plating, anodising, burnishing or chromating, we coordinate external suppliers and negotiate fair prices and reliable delivery times.

Component assembly

Should you require it, our expert team can turn your precision parts into assemblies ready for installation.

You get the utmost precision in assembly, ensuring that your parts work perfectly together.

You can rely on us.

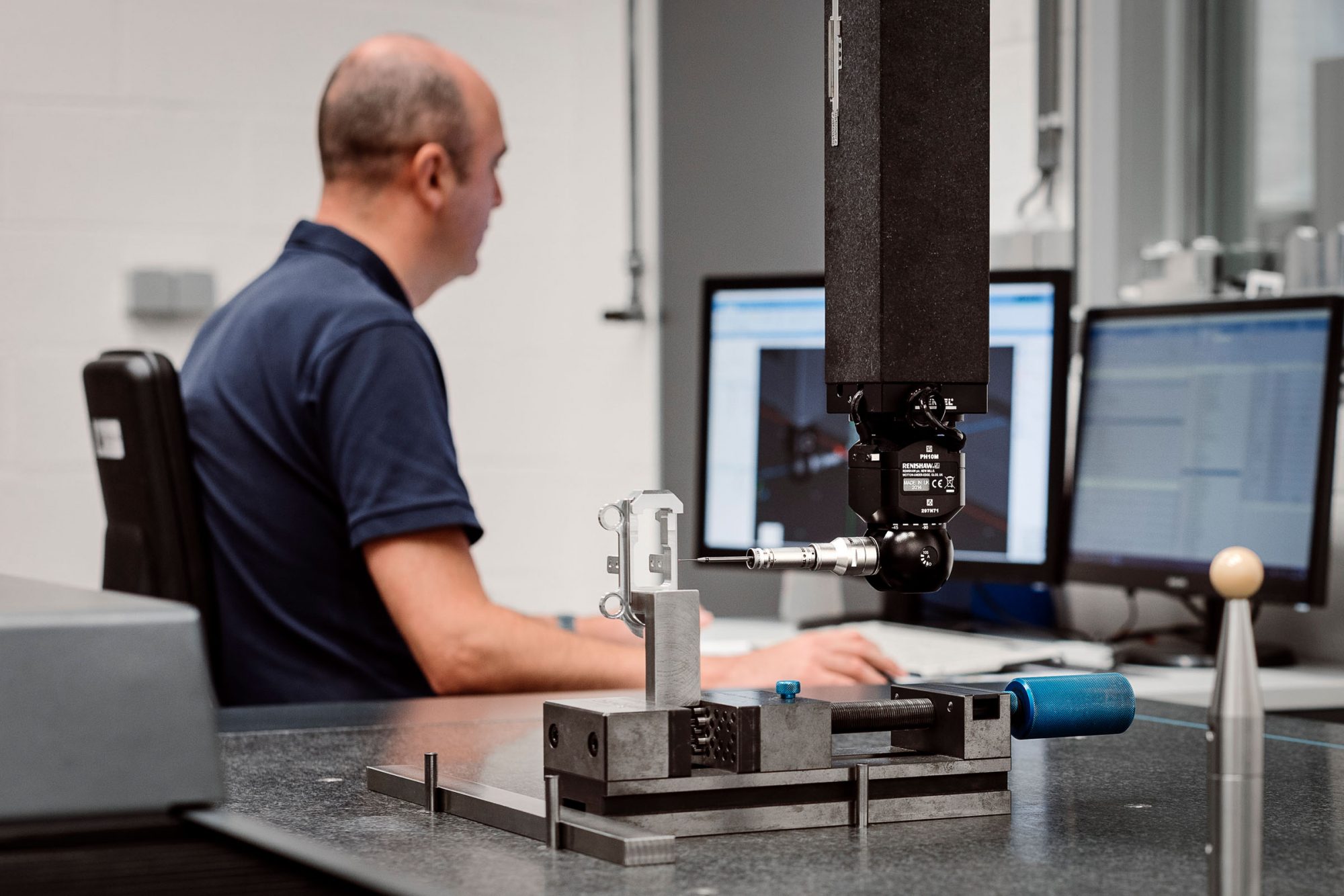

Quality assurance

We guarantee perfect quality.

Mockel is certified to the strictest industrial standards: ISO 9001:2018 and EN 9100.

Our quality assurance meets the most stringent technological requirements.

We perform comprehensive quality assurance in air-conditioned rooms.

Logistics

With our many years of experience, we can offer customised packaging solutions tailored precisely to the material and design of your high-precision parts and assemblies.

This ensures that the quality of your product is maintained all the way to installation, regardless of where it is heading.